Transparent organic–inorganic hybrid photoresist enables precision machining of optical microstructures

- Get link

- X

- Other Apps

Researchers at Beijing University of Chemical Technology (BUCT) and BOE Technology Group Co., Ltd. (BOE) have developed a novel type of transparent organic–inorganic hybrid photoresist with highly tunable refractive index.

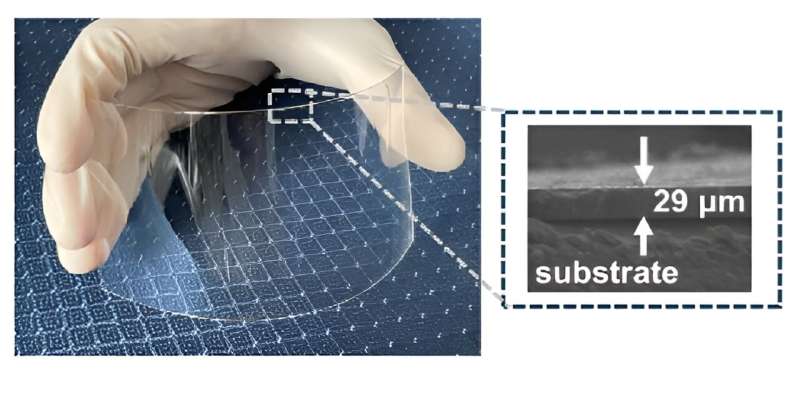

The study, «A Transparent Photoresist Made of Titanium Dioxide Nanoparticle-Embedded Acrylic Resin with a Tunable Refractive Index for UV-Imprint Lithography,» published in Engineering presents the synthesis of transparent photoresist made of titanium dioxide nanoparticle-embedded acrylic resin with a tunable refractive index of up to 2.0 (589 nm) after being cured by ultraviolet (UV) light, while maintaining both a high transparency of over 98% in the visible light range and a low haze of less than 0.05%.

The precision machining of optical microstructures can be imprinted easily and efficiently using the hybrid resin, which acts as a light guide plate to guide the light from the side to the top in order to conserve the energy of the display device.

In recent years, with the rapid development of electronic technology, the display devices have been used in all aspects of life. Optical materials are capable of controlling and regulating light and form the basis of optical devices, which have wide applications in fields such as flat panel display, lens, smart wearable, and augmented reality (AR)/virtual reality (VR) display.

The refractive index is the basic property of optical materials and it is generally accepted that components made of optical resin with a relatively high refractive index are smaller, lighter, and have wider applicability than those made of ordinary optical materials for the same focal length requirements.

Currently commercialized organic optical materials, such as epoxy resins, polymethyl methacrylate, polycarbonate, polystyrene, and silicone resins, are limited by the structural properties of the organic molecules and polymer chains, and the refractive index of the materials is in the range of 1.4–1.6.

To tune the refractive index of UV-curable resin, researchers have tried to add inorganic nanoparticles with high refractive index into the acrylic resin. According to the structural characteristics and application conditions of organic–inorganic hybrid photoresist in optoelectronic display device, the work focused on the optimization of titanium dioxide nanoparticle-embedded acrylic resin.

The refractive index of hybrid photoresist reaches 1.67 at 589 nm when the titanium dioxide content is 30 wt% in the hybrid film, while the refractive index of pure resin is only 1.53. The researchers tested the hybrid material by using electron microscopy imaging and atomic force microscopy analysis.

It is confirmed that the titanium dioxide nanoparticles can be uniformly dispersed in the composite material and the hybrid film exhibits outstanding flatness and a roughness of only 0.196 nm.

To bring newly-developed nanotechnology and nanocomposites with excellent performance out of the laboratory and transform them into new device products, the joint research group of BUCT and BOE has applied the organic–inorganic hybrid photoresist for precision machining of optical microstructures as the light guide plates for flat-panel display devices.

The researchers also developed light-curable resins with an ultrahigh refractive index of 2.0 (589 nm) via a change of the basic polymer material and in the amounts of titanium dioxide nanoparticles. They are also interested in using their material for various applications.

The knowledge obtained from both laboratory and commercial experiments on photon regulation at various nanoscale and microscale interfaces is expected to assist in the promotion of human health via high-precision medical, lighting, and new display products.

More information:

Yinglu Liu et al, A Transparent Photoresist Made of Titanium Dioxide Nanoparticle-Embedded Acrylic Resin with a Tunable Refractive Index for UV-Imprint Lithography, Engineering (2024). DOI: 10.1016/j.eng.2023.12.014

Citation:

Transparent organic–inorganic hybrid photoresist enables precision machining of optical microstructures (2024, June 12)

retrieved 16 June 2024

from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

- Get link

- X

- Other Apps

Comments

Post a Comment